As part of its “Factory of the future” strategy, Safran Helicopter Engines has inaugurated its first automated production line at its Bordes plant. The new line will manufacture every turbine blade used in the company’s product line. It represents a breakthrough, in terms of quality and competitiveness, coupled with a reduction in production cycle and tighter cost control. The time taken to build each blade will be cut by half.

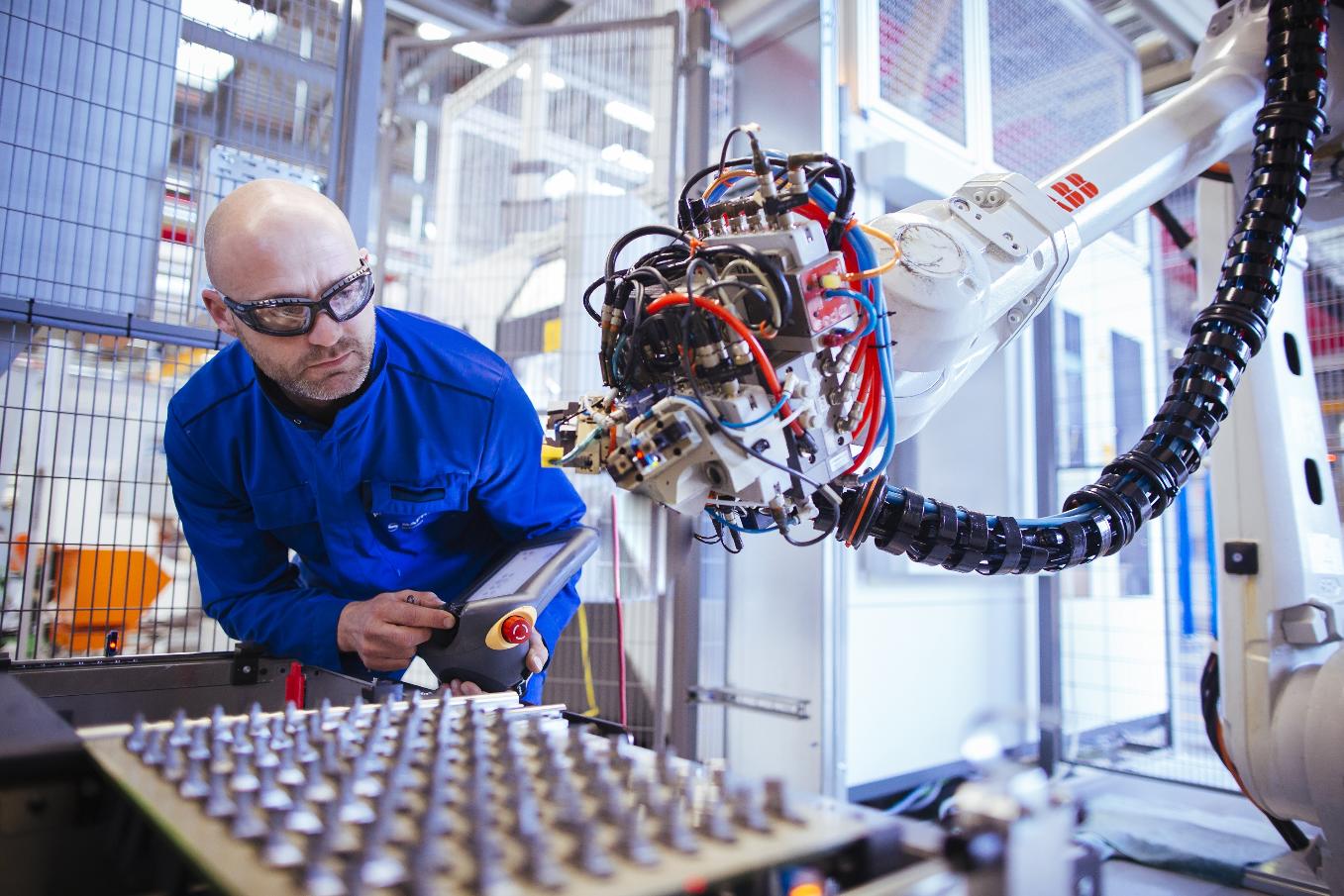

With a 900 square metre footprint, the new production line features several robots and automated cells capable of performing every process (milling, polishing, etching, 3-D control, and surface finishing) from raw material to the finished, ready-to-assemble turbine airfoil. Operators have been locally trained to adapt their skills to this new production line, which can produce more than 100,000 airfoils a year with tolerances measured in microns.

Safran Helicopter Engines’ “Factory of the future” programme was launched in 2010, with the opening of the Joseph Szydlowski plant in Bordes (Pyrénées-Atlantiques). This was followed by the Mantes-Buchelay (Yvelines) plant, which opened in 2011 and, in 2015, the Cap 2020 Tarnos modernization programme. Also in 2015, Safran Helicopter Engines introduced the serial production of additive manufactured components in Bordes.