The Nièvre-based company is capitalizing on its TM-Fast ® innovation to further penetrate the MRO market. It also intends to position itself in the more electric aircraft and air mobility markets.

Improved preventive maintenance

Texys Group took advantage of the work done around the CLIMA collaborative project - Design of Damping Mechanical Connections - to develop an innovation that would open the doors to MRO. The purpose of its participation in this program conducted alongside Airbus Defence and Space was, in fact, " to equip assemblies for aerostructures in order to know the level of torque of mechanical assemblies and to monitor, thus, the tightening tension of a considered screw ", recalls Emmanuel Esnault, Texys Group's managing director.

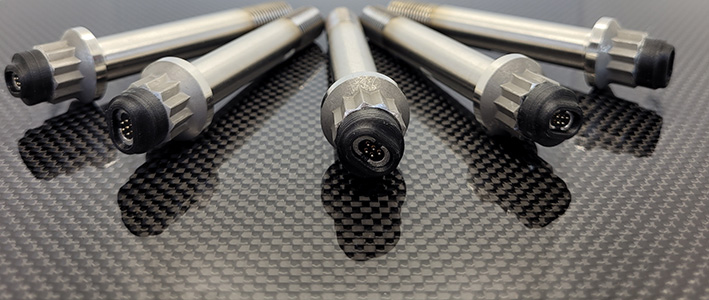

From this work came the creation of the TM-Fast ® technology, which, since 2019, has been patented in both Europe, China and the United States, the main MRO markets. Thanks to this instrumented screw for monitoring tightening loads on parts with diameters from M4 to M33, Texys Group (49 employees, €6.4 million in sales) has thus entered the MRO market, its customers being either screw manufacturers or directly aeronautical manufacturers.

These customers have understood the interest they could gain from this technology in the field of preventive maintenance. Especially since the process resulting from the machining of the screw head and the installation of strain gauges inside it does not lead to any modification of the mechanical properties of the screw, while ensuring real-time measurement of tightening tensions. This is summarized by Guillaume Vauzelle, technical sales engineer at Texys Group, who points out that " Texys is one of the few companies to master the entire value chain from the bonding of the strain gauges fixed inside the screw head to the wireless transmission in real time of the values through the signal conditioning "

Better than a torque wrench

Beyond its ease of implementation at the customer's site, TM-Fast ® is presented, moreover, as a more accurate and reliable solution than a torque wrench. This technology also allows for the optimization of the sizing of the screws and everything that goes with them. The benefits therefore do not only result in the improvement of preventive maintenance.

An improvement of the wireless version - two other versions exist : wired and embedded intelligence - is already under development. It will allow consultation of the information contained in the screw from a longer distance during maintenance operations. It will facilitate, thus, the work carried out by the operators according to the tension of the assembly.

Solutions for hydrogen

Beyond a number of solutions already used by aerospace manufacturers such as charge amplification sensors, thermocouple conditioners and strain gauges, the Varennes-Vauzelles company is continuing its work to develop ranges of non-intrusive current sensors (up to +/- 1 300 A) in the context of more electric aircraft or other applications. In addition, one of the group's subsidiaries, which is also present in the United States and Germany, has seized opportunities related to the air mobility market.

" We have developed specifically for air, land and sea mobility a complete hydrogen fuel cell propulsion solution with a power of up to 100 kW. We will therefore on this point develop the entire ecosystem of sensors that will include both current, dielectric liquid conductivity, pressure temperature humidity hydrogen and leak detection sensors. We already have a first customer project for light aviation. However, confidentiality clauses prevent us from revealing the name of this customer, which will benefit from this new technology as early as the end of 2022 " adds Emmanuel Esnault.

Texys Group is also working intensively in the field of fiber optic measurements and, in particular, in those performed via Bragg gratings. This fiber optic technology consists of measuring up to forty microdeformations or temperatures, for example, on a single fiber from a few cm to several km long. " Thanks to this integration of optical fibers in structural parts, we are part of a reduction in maintenance operations and optimization of part sizing " the executive concludes.

Découvrez cet article sur Air&Cosmos