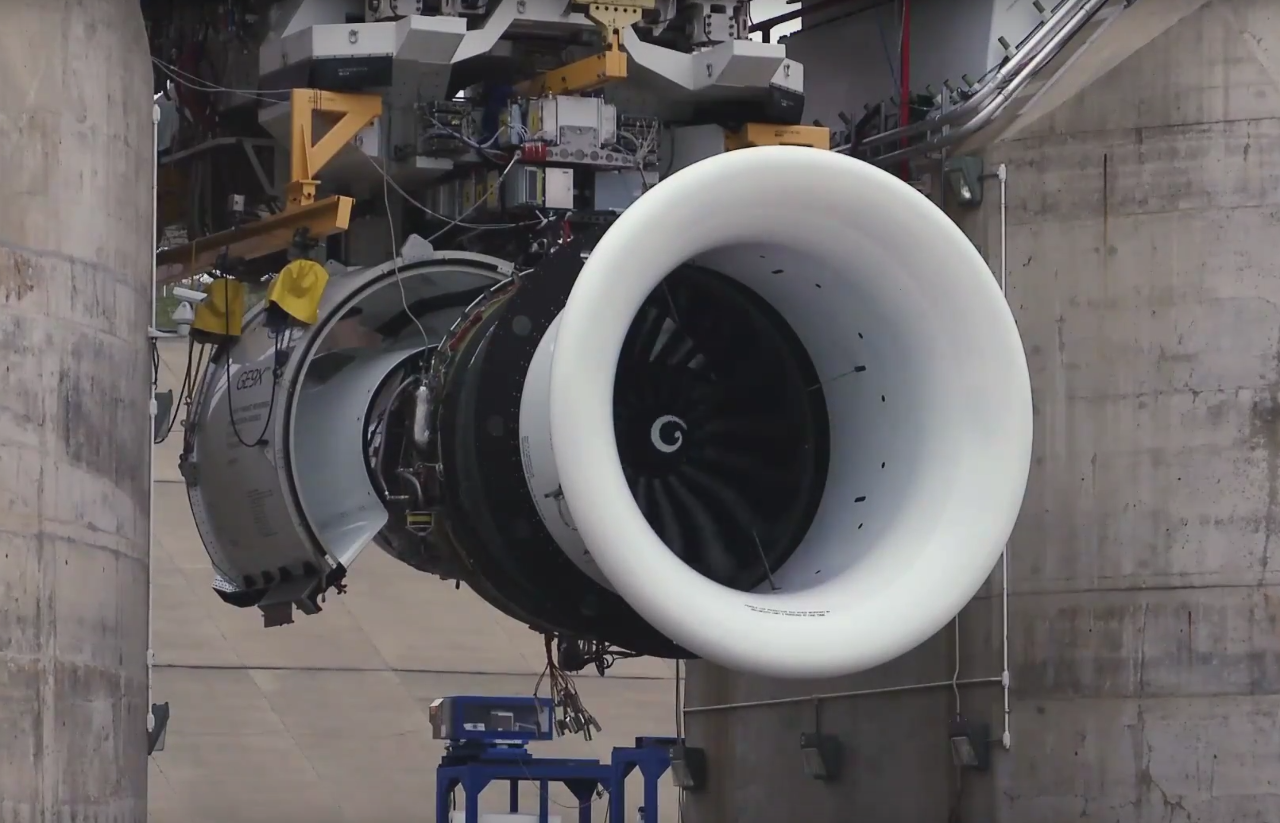

GE says it has completed the second phase of GE9X CMC (ceramic matrix composite) component testing in a GEnx demonstrator engine. CMC materials will be used in the combustor and turbine of the GE9X engine, which will power the Boeing 777X.

The demonstrator engine accumulated 1,800 cycles in the latest round of tests, which included exposure to harsh environmental conditions of dust and debris. The level of debris exposure is described as equivalent to about 3,000 take-off and landing cycles.

For the second round of tests, the demonstrator engine utilized the same CMC combustor liners, HPT stage 1 shrouds and HPT stage 2 nozzles from the first round of tests in September 2015 along with the addition of the HPT stage 1 CMC nozzles.

CMCs (silicon carbide ceramic fibres and ceramic matrix, enhanced with proprietary coatings) are lighter than metal alloys, and reduced weight improves fuel efficiency and durability. CMCs are also more heat-resistant than metal alloys, allowing the diversion of less cooling air into an engine's hot section. By using this cooling air in the engine flow path, an engine runs more efficiently at higher temperature.

The GEnx CMC demonstrator engine also incorporated non-CMC GE9X parts, including the new 3D additive manufactured lightweight low-pressure turbine titanium aluminide (TiAl) blades produced at Avio Aero and the next-generation HPT stage 1 blades with advanced cooling technology.

Certification testing on the GE9X programme will begin in the first half of this year along with flight testing on GE Aviation's flying test bed. Engine certification is expected in 2018.

IHI Corporation, Safran Aircraft Engines, Safran Aero Boosters and MTU Aero Engines AG are participants in the GE9X engine programme.