Cranfield Aerospace Solutions (CAeS) has selected Evolito, a UK technology innovator, as the motor and inverter supplier for its technology demonstrator, the Fresson project. The twin-engine aircraft is scheduled to make its maiden flight at the end of this year.

Evolito motors for the Fresson project...

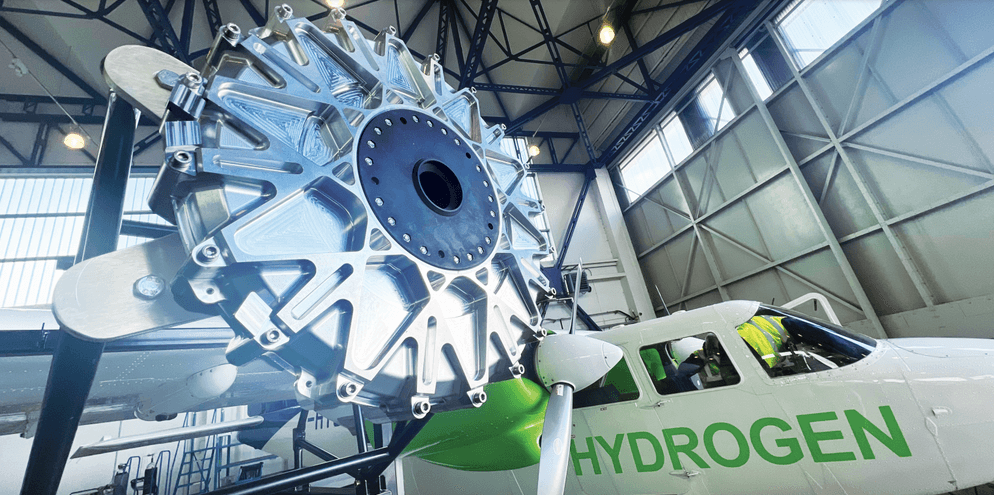

Cranfield Aerospace Solutions (CAeS) has selected Evolito, a UK technology innovator, as the motor and inverter supplier for its hydrogen aircraft demonstrator - the Fresson project. Evolito joins Reaction Engines and Ricardo as technology collaborators on the Fresson project. Based in Oxfordshire, Evolito is the aerospace spin out (a new stand-alone company created by former employees) of Yasa, the global pioneer of axial-flow electric motors for automotive use.

...Axial flow...

Producing the electric propulsion system, Evolito's motors are smaller, lighter and typically four times more powerful than radial flux solutions, making them, according to its manufacturer, ideally suited to emerging zero-emission aviation markets. Evolito's axial flux technology requires up to 75% less iron, less copper and fewer permanent magnets than competing radial solutions, making it lighter and more environmentally friendly. An axial flux motor is an electric motor construction in which the air gap between the rotor and stator, and thus the direction of magnetic flux between the two, is aligned parallel to the axis of rotation, rather than radially as in the concentric cylindrical geometry of the more common radial gap motor. While this geometry has been used since the creation of the first electromagnetic motors in the 19th century, its use remained confidential until the widespread use of strong permanent magnets and the development of brushless DC motors, which allow the advantages of this geometry to be better exploited.

...And lighter mass

For the Fresson project, the mass (or weight) of the motor and controller is an important component of the total mass of the hydrogen electric propulsion system, which must be minimized to maximize the payload and range that the emissions-free aircraft can achieve. The engine also has efficiency advantages due to its new cooling systems, which means the unit never overheats and can operate at peak performance at all times. The Fresson project is centered around converting the propulsion system of a 9-seat Britten-Norman Islander aircraft to hydrogen gas via a fuel cell system, with the aim of putting it into commercial service by 2026 on routes of up to 200 km. The aircraft is expected to make its first flight in late 2023, according to Cranfield Aerospace Solutions' schedule.

Découvrez cet article sur Air&Cosmos