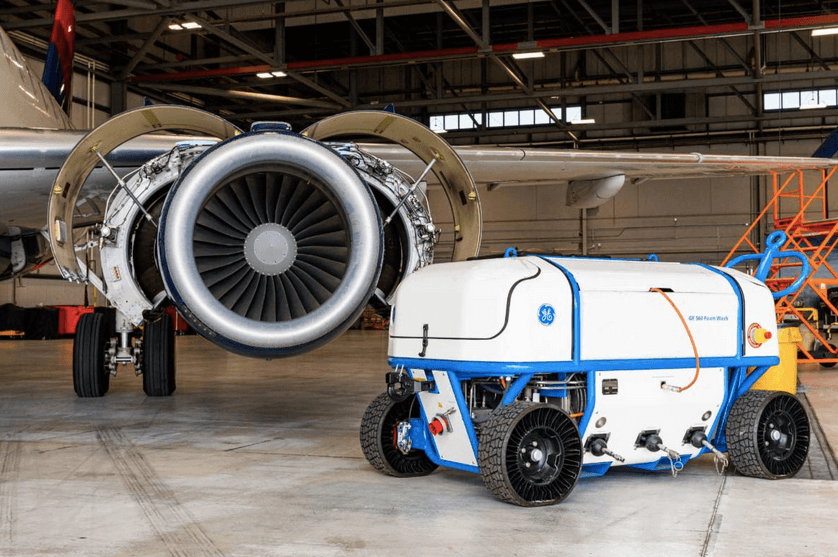

Using foam instead of water to clean turbojet engines is the idea behind GE's 360 Foam Wash cleaning system, the first of which will be used by SkyWest.

Foam to replace water

GE Aerospace has granted SkyWest Airlines, a subsidiary of SkyWest, a technical license to use GE's 360 Foam Wash system on its CF34 aircraft engines, making SkyWest the first North American operator to obtain a license for this patented engine cleaning system. The 360 Foam Wash system could help SkyWest Airlines avoid up to 13,900 tonnes of CO2 emissions per year by replacing some water washes with foam washes for CF34 engine cleaning.

A specially formulated proprietary solution

GE's 360 Foam Wash is an alternative to water washing for engine maintenance. It can help restore engine performance, reducing fuel consumption and improving time on wing. The process involves injecting a specially formulated proprietary solution that reduces deposit build-up in the engine, which can lower engine exhaust temperatures and improve engine compressor efficiency.

Testing and training

The license was granted following technology testing and equipment training. SkyWest Airlines' aircraft technicians can now perform this new cleaning technique themselves to maintain the fleet of CF34 engines powering the airline's Embraer 175s and MHI CRJ700 and CRJ900 aircraft. The Foam Wash system is self-contained, enabling it to be used both inside and outside maintenance hangars. Foam Wash is approved for use on many GE engine programs, including GE90, GEnx and CF34 models.

Découvrez cet article sur Air&Cosmos