GE has announced plans to acquire two European suppliers of additive manufacturing (or 3D printing) equipment, Arcam AB and SLM Solutions Group AG, for $1.4bn. Both companies will report to David Joyce, President & CEO of GE Aviation. Joyce will lead the growth of these businesses in the additive manufacturing equipment and services industry. In addition, he will lead the integration effort and the GE Store initiative to drive additive manufacturing applications across GE.

GE expects to grow the new additive business to $1bn by 2020 at “attractive” returns and also expects to reduce product costs by $3-5bn across the company over the next ten years.

Arcam AB, based in Mölndal, Sweden, invented the electron beam melting machine for metal-based additive manufacturing, and also produces advanced metal powders. Its customers are in the aerospace and healthcare industries. Arcam generated $68m in revenues in 2015 with approximately 285 employees.

SLM Solutions Group, based in Lübeck, Germany, produces laser machines for metal-based additive manufacturing with customers in the aerospace, energy, healthcare, and automotive industries. SLM generated $74m in revenues in 2015 with 260 employees.

The two companies will bolster GE’s existing material science and additive manufacturing capabilities. GE has invested approximately $1.5bn in manufacturing and additive technologies since 2010.

The additive effort will utilize GE’s global ecosystem, but be centred in Europe. GE will maintain the headquarters locations and key operating locations of Arcam and SLM, as well as retaining their management teams and employees. These locations will collaborate with the broader GE additive ecosystem including the manufacturing and materials research centre in Niskayuna, New York, and the additive design and production lab in Pittsburgh, Pennsylvania. They will also complement the technologies brought on by other key acquisitions such as Morris Technologies and Rapid Quality Manufacturing.

In July, GE Aviation introduced into airline service its first additive jet engine component – complex fuel nozzle interiors – with the Leap jet engine of CFM International, a 50/50 joint company of GE and Safran Aircraft Engines of France.

More than 11,000 Leap engines are on order with up to 20 fuel nozzles in every engine, thus setting the stage for sustainably high and long-term additive production at GE Aviation’s Auburn, Alabama, manufacturing plant. Production will ramp up to more than 40,000 fuel nozzles using additive by 2020. GE Aviation is also using additive manufacturing to produce components in its most advanced military engines.

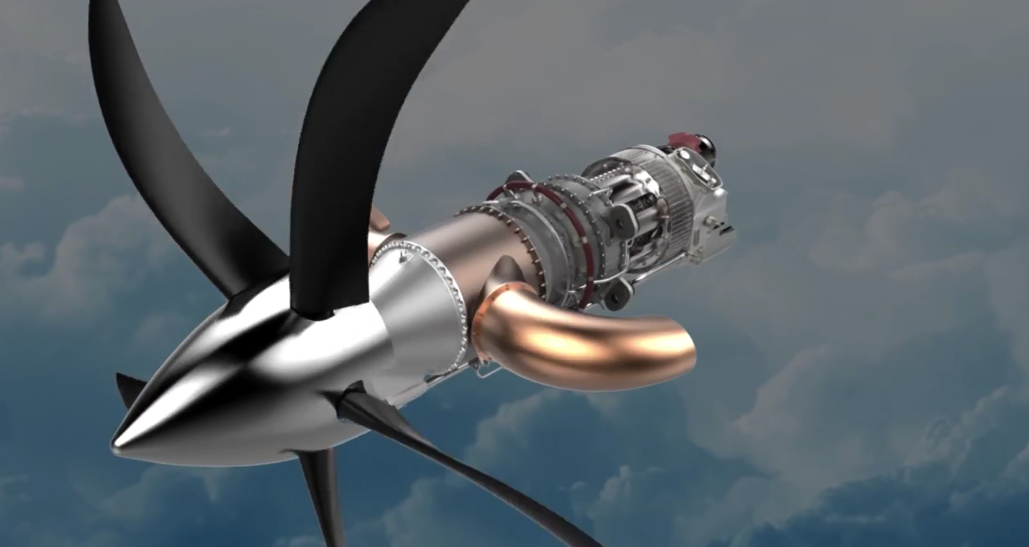

In the general aviation world, GE is developing the Advanced Turboprop Engine (ATP) for Cessna’s new Denali single-engine turboprop, with a significant portion of the entire engine produced using additive manufacturing.